|

|

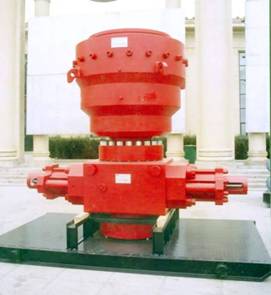

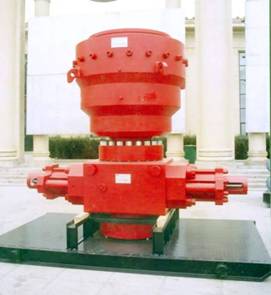

Blowout Preventer (BOP)

Group BOP

Our BOP is manufactured based on the strict relevant technical standards. JM controls all procedures meticulously from the design to the ex-works according to the ISO9001 standards. JM performs overall procedure quality tracing and controlling of the major parts in BOP.

The Group BOP was combined by Annular BOP and Ram BOP:

1. Annular BOP

In case of blowout and well-sealing is needed, high pressure oil coming from control system enters the bottom closing chamber from bottom Inlet to push piston moving upward. The movement of piston forces rubber core to move upward along the sphere surface, then supportlng ribs get closer to push the internal rubber moving towards the wellhead center to fulfill the function of sealing drill equipment or the wellhead. When unlocking the seal is needed, hydraulic oil pushes the piston moving downward and the rubber core will reset to its original position under Its elastic force. In case of blowout and well-sealing is needed, high pressure oil coming from control system enters the bottom closing chamber from bottom Inlet to push piston moving upward. The movement of piston forces rubber core to move upward along the sphere surface, then supportlng ribs get closer to push the internal rubber moving towards the wellhead center to fulfill the function of sealing drill equipment or the wellhead. When unlocking the seal is needed, hydraulic oil pushes the piston moving downward and the rubber core will reset to its original position under Its elastic force.

Structure Characteristics

1. The connection between top cap and housing, top and bottom ends adopt fianges and bolts.

2. Semlsphere rubber core has many advantages, such as not easy folding back, big volume of rubber storage. Under the well pressure, the piston pushes the rubber core upward to form a funnel shape. The funnel effect of rubber core increases its sealing performance and life span.

3. Characteristics of the sealing structure

l) The BOP has three important sealing positions: piston external surface seal, piston Internal surface seal and mud blocking ring seal.

2) Radial direction cross section of the piston comes of the shape "Z", which makes the piston have short stroke length, low height and big diameter.

3) There are two wear-rings stick to the external surface of the piston and a wear-ring stick to the Internal surface of the houslng.The structure prevents metal to metal contact and protects piston and housing.

Please click here to check the Annular BOP parameters, or contact us for more information.

2 Ram BOP

Ram BOP is mainly composed of housing, side gate, hydro-cylinder, cylinder cap, piston, piston rod, lock shaft, sealing parts, ram, etc. Oil well's sealing or opening is achieved by moving ram, which is driven by piston rod and piston with hydraulic force. Ram BOP is mainly composed of housing, side gate, hydro-cylinder, cylinder cap, piston, piston rod, lock shaft, sealing parts, ram, etc. Oil well's sealing or opening is achieved by moving ram, which is driven by piston rod and piston with hydraulic force.

Compared with products of other structures, the product has the following characteristics:

1. The combined type hinge seat makes it's convenient to maintain and disassemble the product.

2. In order to guarantee the reliabie sealing, the shaft sealing parts are locked by stainless plates and screws.

3. Seal ring of the side gate adopts reinforced rubber material to guarantee side gate's life span and its reliable seal.

4. The ram structure makes it's easy to change the rubber core and fore rubber core on the ram. The floating top rubber core can increase the seal reliability. A leading block, which mounted on the foreside of ram assembly, makes the drilling tools have automatic centering function.

5. The horizontal secondary seal equipment of side gate piston rod and sealing leakage hole not only guarantee the exchange ability of the side gate, but make leakage checking and secondary sealing operation be convenient.

6. Guide rib in the ram chamber of the housing can limit the moving direction of the ram.

7. The two-way seal of piston rod can prevent the inter-leakage between well fluid and hydraulic oil. And installation and dismantling of packing set is convenient.

Please click here to check the Ram BOP parameters, or contact us for more information.

|